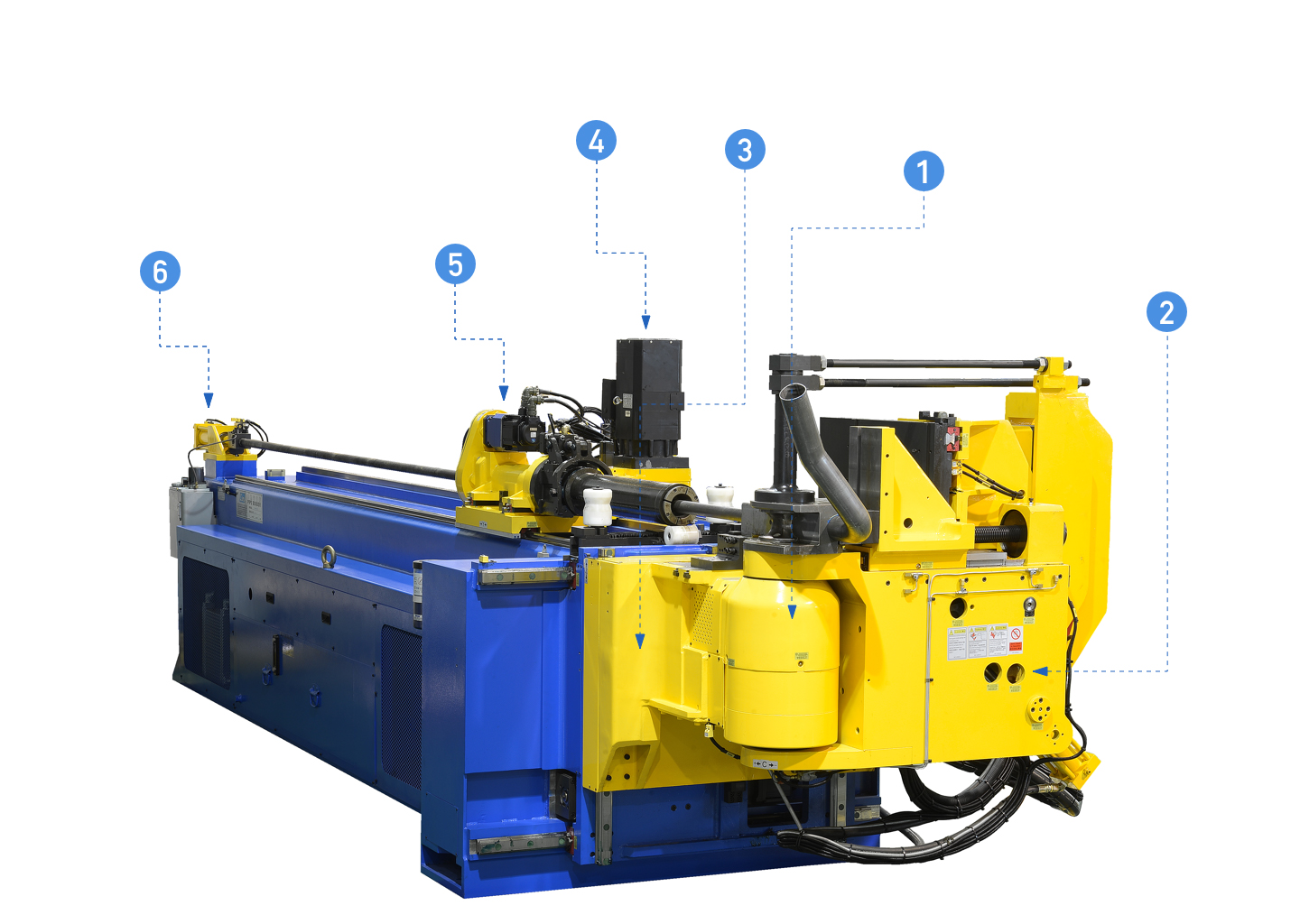

MBE

- bend-arm (C-axis) by servo motor with exclusive transmission gears, tolerance within ±0.01°

-

- clamp die by hydraulic

- pressure die by hydraulic

- side booster by hydraulic

-

- tools/radii shifting :

- motion up-down by servo motor

- motion left-right by servo motor

- carriage (Y-axis) by servo motor with programmable speed

- collet (B-axis) grip by hydraulic, rotation by servo motor

- mandrel by hydraulic with automatic lubrication & anticipated retraction

- work-head capable of linear motion, serves clockwise and counterclockwise bending

-

- Controller :

- Industrial PC assorted with touch-screen display, capable of bending simulation, 3D preview and interference detection

- programmable speed for servo axes

- with USB port, easy for data transfer

- convertible between manual / automatic mode

- convertible between inch / metric setting

- convertible between XYZ / YBC axes

- capable of reading igs/stp file

|

CNC electric hybrid MBE / MRE tube bending machine

|

|||||||

|

OD |

WT |

CLR |

mandrel working distance |

tooling capacity |

roll bending |

rear booster |

CSM part no. |

|

18

|

1.6

|

10-80

|

1200

|

3

|

|

|

18 MBE

|

|

25.4

|

1.5

|

15-120

|

1500

|

3

|

|

|

25 MBE

|

|

30

|

2

|

15-120

|

2200

|

3

|

|

|

30 MBE

|

|

38.1

|

1.8

|

25-150

|

2200

|

3

|

|

|

38 MBE

|

|

50.8

|

2

|

30-220

|

2500

|

3

|

|

|

50 MBE

|

|

65

|

2.5

|

35-250

|

2500

|

3

|

|

|

65 MBE

|

|

80

|

2.5

|

40-280

|

3500

|

3

|

|

|

80 MBE

|

|

100

|

3

|

30-300

|

3500

|

3

|

|

|

100 MBE

|

|

65

|

2.5

|

35-250

|

2500

|

3

|

|

servo

|

65 MBE-RBE

|

|

80

|

2.8

|

40-280

|

3500

|

3

|

|

servo

|

80 MBE-RBE

|

|

100

|

3.6

|

30-300

|

3500

|

3

|

|

servo

|

100 MBE-RBE

|

|

127

|

3.8

|

80-400

|

4000

|

3

|

|

servo

|

130 MBE-RBE

|

|

18

|

1.6

|

10-80

|

1200

|

3

|

yes

|

|

18 MRE

|

|

25.4

|

1.5

|

15-120

|

1500

|

3

|

yes

|

|

25 MRE

|

|

30

|

2

|

15-120

|

2200

|

3

|

yes

|

|

30 MRE

|

|

38

|

1.8

|

25-150

|

2200

|

3

|

yes

|

|

38 MRE

|

|

50.8

|

2

|

30-220

|

2500

|

3

|

yes

|

|

50 MRE

|

|

65

|

2.5

|

35-250

|

2500

|

3

|

yes

|

|

65 MRE

|

|

80

|

2.5

|

40-280

|

3500

|

3

|

yes

|

|

80 MRE

|

|

65

|

2.5

|

35-250

|

2500

|

3

|

yes

|

servo

|

65 MRE-RBE

|

|

80

|

2.8

|

40-280

|

3500

|

3

|

yes

|

servo

|

80 MRE-RBE

|

|

100

|

3.6

|

30-300

|

3500

|

3

|

yes

|

servo

|

100 MRE-RBE

|

|

127

|

3.8

|

80-400

|

4000

|

3

|

yes

|

servo

|

130 MRE-RBE

|

|

152.4

|

3

|

90-400

|

4000

|

3

|

yes

|

servo

|

150 MRE-RBE

|

- videos