3D bevel cutting with automatic bundle loading & unloading

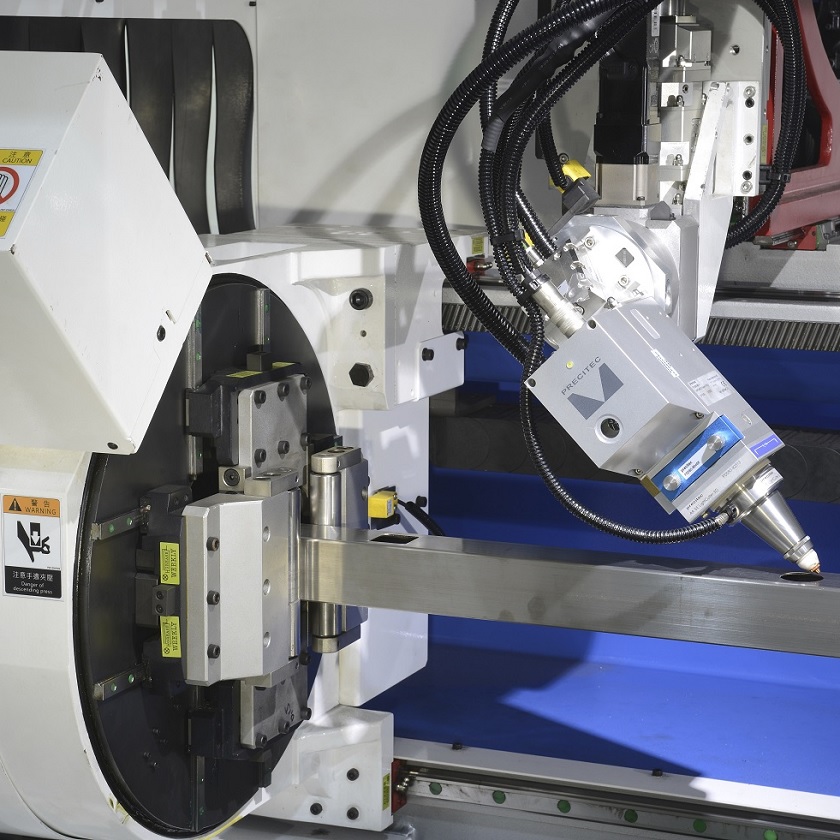

1.Laser head bevel cutting :

- Integrates CSM’s exclusive transmission system with Precitec tilting laser head, capable of 3D bevel cutting in rapid speed

2.Clamping chucks :

- Altogether 3 chucks (Y1-Y2-Y3), capable of automatic aligning and centering, facilitates fast feeding and precise positioning

- Clamping by four pneumatic cylinders driven by dual pneumatic sources, capable of clamping asymmetrical tube tightly and precisely without deviation

- Optimized for clamping either circular, or rectangular、square、elliptic、obround、asymmetrical tube

- Compact in size and weight. Chuck Y2 is possible to overtake laser head, capable of finishing workpiece without end waste

3.Loading :

- Capable of bundle loading, automatic tube diameter & length detection、seam detection

- Applicable to tube with different shape and OD

4.Unloading :

- Automated by 2 servos, capable of supporting tube steadily throughout the cutting cycle

- Capable of relocating finish parts to desired location

|

Specification |

Unit |

LS150-5E |

LS220-5E |

LS360-5E |

|

Cutting capacity / OD |

mm |

16~150 |

18~220 |

25.4~360 |

|

Standard raw tube loading length |

mm |

6300 |

6300 |

8000 |

|

Clamping length for zero end waste cutting |

mm |

650 |

765 |

TBA |

|

X-axis working distance |

mm |

160 |

270 |

270 |

|

X-axis speed |

mm/sec |

250 |

250 |

500 |

|

Z-axis working distance |

mm |

310 |

384 |

|

|

Z-axis speed |

mm/sec |

352 |

352 |

250 |

|

A-axis turning angle |

degree |

±45 |

±45 |

±45 |

|

A-axis turning speed |

degree/sec |

360 |

360 |

600 |

|

Y1/Y2/Y3-axes working distance |

mm |

7100/9000/5300 |

7010/9040/6500 |

9290/1550/5360 |

|

Y1/Y2/Y3-axes speed |

mm/sec |

777 |

777 |

529 |

|

Positioning repeatability |

mm |

±0.03 |

±0.03 |

±0.03 |

|

B-axis speed |

degree/sec |

600 |

450 |

257 |

|

B-axis positioning repeatability |

arcmin |

±8 |

±8 |

±8 |

|

Machine size (length x width x height) |

mm |

11300 x 2800 x 2600 |

13400 x 3800 x 2700 |

17500 x 3300 x 2400 |

|

Machine weight |

kg |

8000 |

8000 |

15000 |